Whether in the automotive-, aerospace- and electrical industry, as well as medical technology and tool and mould construction, or other industries where machining pays an important role – if maximum precision and machining quality are required with high productivity and economy, SCHÜSSLER is the first choice.

You may rely on our decades of experience, well-developed know-how, top quality and fast availability. With SCHÜSSLER Tool Holding Systems, you will produce faster and better and more cost effective. Choose your favourites from over 1800 products:

> Collet chucks ER and ER „Mini“

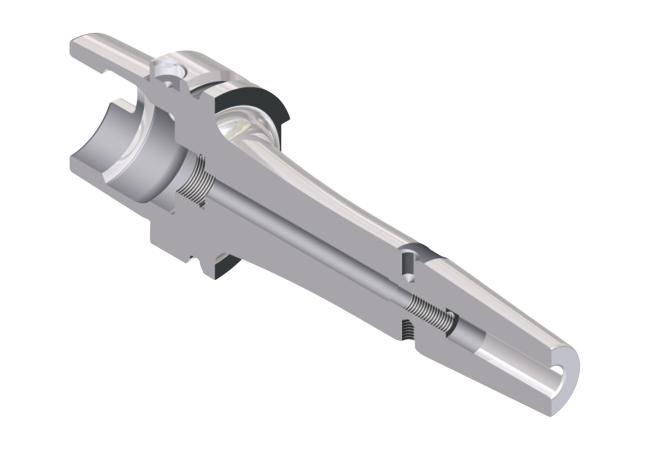

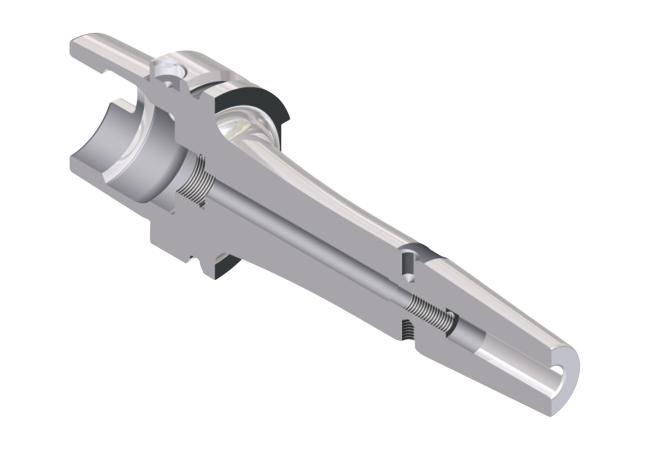

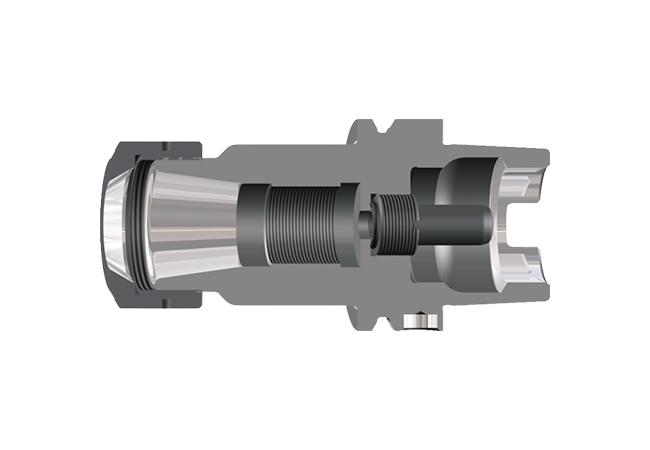

> HAWK EYE® HPC Precision ER collet chuck and HAWK EYE® „Mini“

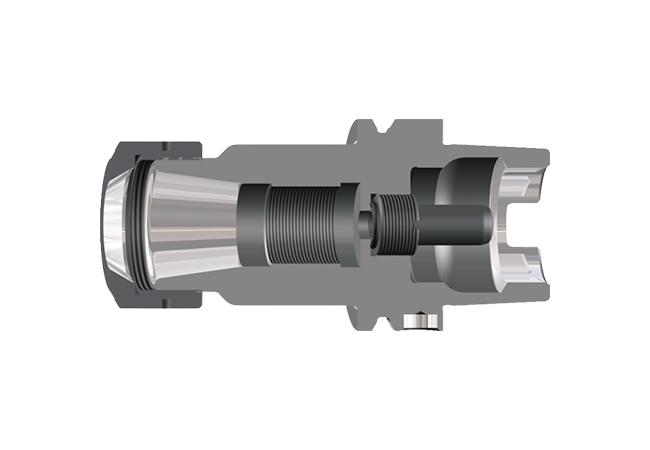

> Shrink fit chuck 4,5° and 3° (slim)

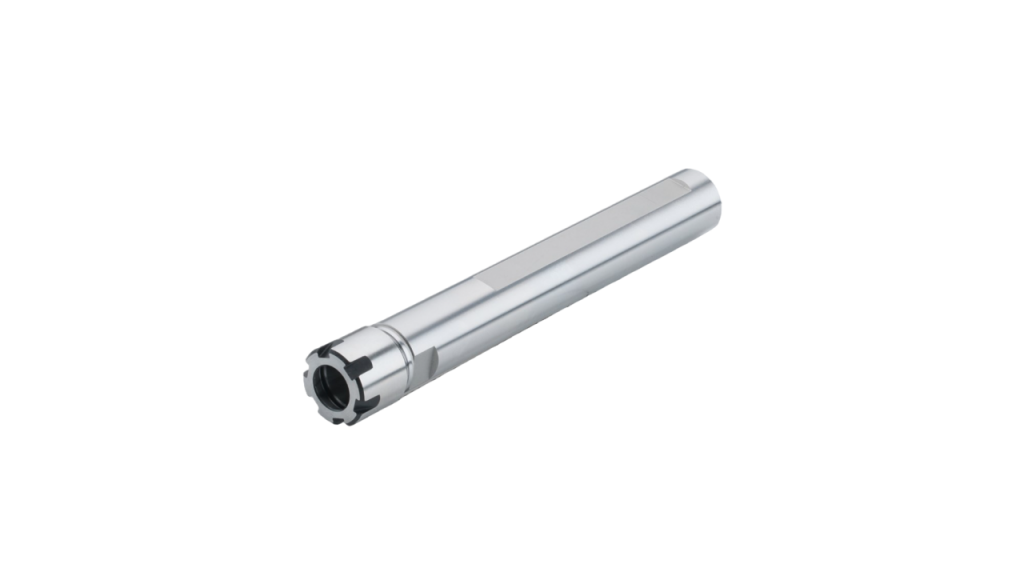

> End mill holder Weldon

> Tool holders with coolant supply to the tool (Cool Tool)

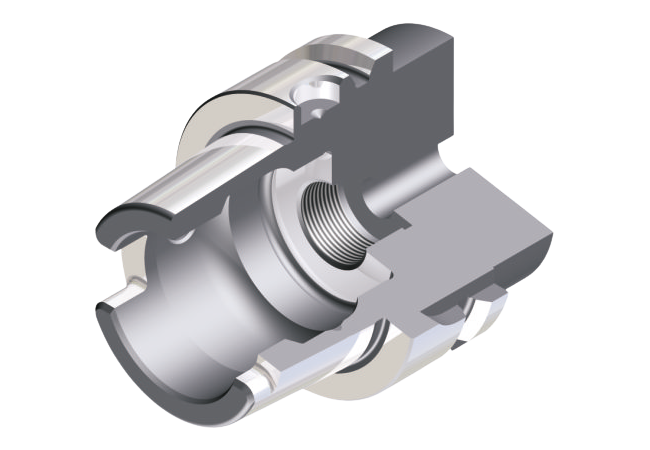

> Shell mill holder

All tool holders are available in different length versions with all common taper shanks:

> HSK 40 / 50 / 63 / 80 / Form A

> HSK 32 / 40 / 50 Form E

> HSK 63 Form F

> SK 40 and 50 DIN ISO 7388-1 AD/AF

> MAS BT 30 /40 / 50 DIN ISO 7388-2 JD/FF

> MAS BT 30 / 40 with face contact

> PSC CORUM C4 / C5 / C6 / C8 ISO 26623

Always the best choice – and in order that our tool holders keep our promised performance, we rely entirely on 100 % quality Made in Germany.

This strategy has proved its worth. You benefit from high machining precision and optimum machining results. Tools and spindles are saved, tool life is extended, and the availability of your machines is increased. This not only saves you time and trouble, but also money. And we are looking forward to satisfied, happy and successful customers.

As our calculation example shows, the use of high-quality SCHÜSSLER tool holders lead to significant savings in the tool costs. Even one tool holder can reduce the cost of the tools used in it by more than 6.000 €, with an additional investment of less than 50 €. Who invests in SCHÜSSLER, benefits from a top return!

SCHÜSSLER – the solution for profitable, successful machining

However, the actual savings potential in relation to your entire manufacturing process is a lot higher than the € 6.500 per tool holder. Because SCHÜSSLER quality also contributes to reducing machine and labour costs. Additional, you increase your productivity by:

„Noname“

SCHÜSSLER

Product:

SK-A63 ER-Collet chuck with

standard collet, clamping

diameter ø16 mm

Precision-ER collet chuck with

high performance nut and with precision collet,

Clamping diameter ø 16 mm

85,- €

130,- €

5 years

5 years

Tool costs:

(solid carbide endmill,

coated, Ø16 mm)

130,- €/ piece

130,- €/ piece

2 endmills per week = 96 mills

per year

10% tool life improvement: 1,8

endmills per weerk = 86

endmills pear year

12.480,- €

Savings:

6500,- € (for 45,- € additional costs)

Possible tool cost savings: per used SCHÜSSLER tool holder during a working life of 5 years.

Um die gleichbleibend hohe Qualität unserer Produkte sicherzustellen, arbeiten wir im

gesamten Produktionsprozess nach höchsten Qualitätsmaßstäben. Beginnend bei der Auswahl des Rohmaterials über die eigentliche Fertigung bis hin zur abschließenden sorgfältigen Qualitätskontrolle jeder einzelnen Werkzeugaufnahme – unterstützt durch ein effektives, prozessübergreifendes Qualitätsmanagementsystem, zertifiziert nach ISO 9001:2015.

· 100%-ige Mittenlage der Nuten · perfekten Sitz und Drehmomentübertragung in der Spindel

· besten Rundlauf der Spannschulter (max. 10: 5fach genauer als DIN) · höchste Rundlauf- und Wiederholgenauigkeit · maximale Spannkräfte der Spindel · maximale radiale Steifigkeit

· sicheres Lösen des HSK beim Werkzeugwechsel

· ruhiger, lagerschonender Spindellauf · längere Lebensdauer der Spindel · höchste Werkzeugstandzeiten · bessere Werkstückoberflächen

Runout tolerance of the different

toolholder types:

Toolholder type:

Runout

A < 160

Runout

A ≥ 160

Endmill holder Weldon, Collet cuck,

Shrink fit holder, Endmill holder Whistle Notch

≤ 3 μ

≤ 4 μ

≤ 6 μ

Hard reworked drive slots on HSKtaper guarantees:

· 100% symmetry of the HSK-slots

· perfect seat and torque transfer in machine spindle

Hard reworked HSK-discharge surface garantees:

· safe release of HSK at tool change

All toolholders fine balanced to G2,5 25.000 or max. unbalance ≤ 1 gmm, for:

· smooth and bearing protecting spindle run

· longer spindle life cycle

· maximum tool life

· better milling surface

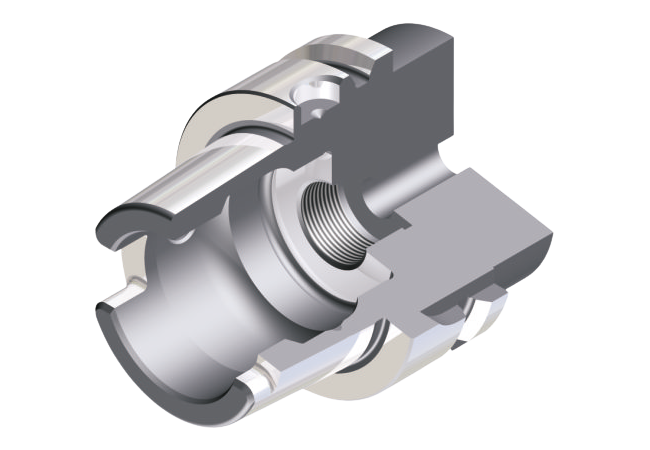

Hard reworked HSK-shoulder guarantees:

· perfect runout of clamping shoulder (max. 10µ : 5 times more accurate than DIN)

· highest runout accuracy

· maximum clamping force in spindle

· maximum radial rigidity

Hard reworked drive slots on HSKtaper guarantees:

· 100% symmetry of the HSK-slots

· perfect seat and torque transfer in machine spindle

Hard reworked HSK-discharge surface garantees:

· safe release of HSK at tool change

All toolholders fine balanced to G2,5 25.000 or max. unbalance ≤ 1 gmm, for:

· smooth and bearing protecting spindle run

· longer spindle life cycle

· maximum tool life

· better milling surface

Hard reworked HSK-shoulder guarantees:

· perfect runout of clamping shoulder (max. 10µ : 5 times more accurate than DIN)

· highest runout accuracy

· maximum clamping force in spindle

· maximum radial rigidity

Runout tolerance of the different

toolholder types:

Toolholder type:

Runout

A < 160

Runout

A ≥ 160

Endmill holder Weldon, Collet cuck,

Shrink fit holder, Endmill holder Whistle Notch

≤ 3 μ

≤ 4 μ

≤ 6 μ

You can download our complete product catalogue here and have a look at our various models of tool holders. With the following selection you can also find the right tool for your machining task:

Tool holder with HSK

HSK-A 40/50/63/80/100

HSK-E 32/40/50

HSK-F 63

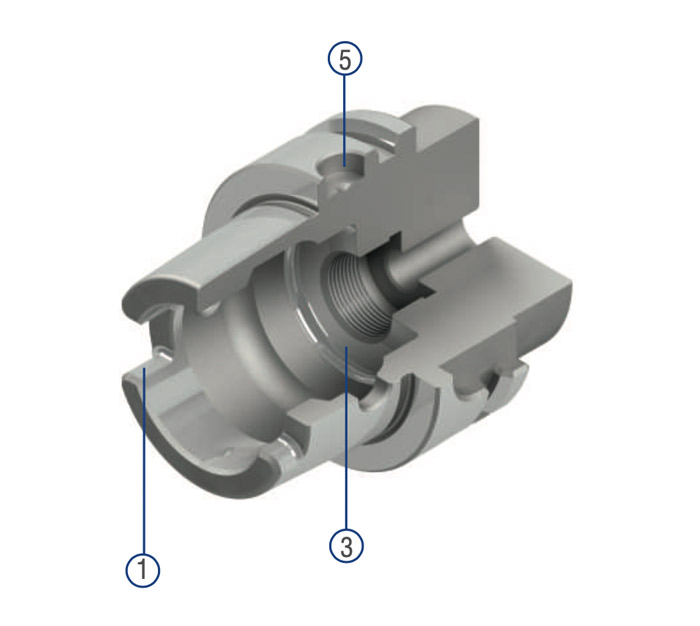

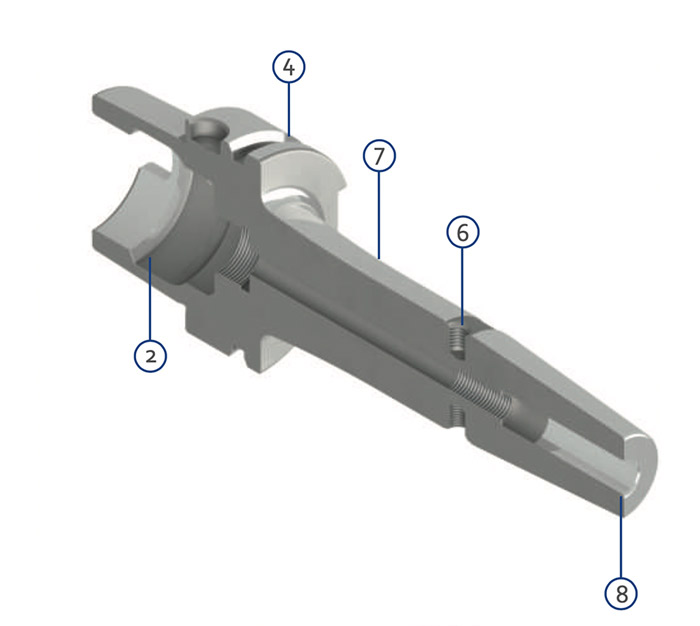

ER-Collet Chuck

ER-Collet Chuck “Mini”

ER-collet chuck corrosion-protected

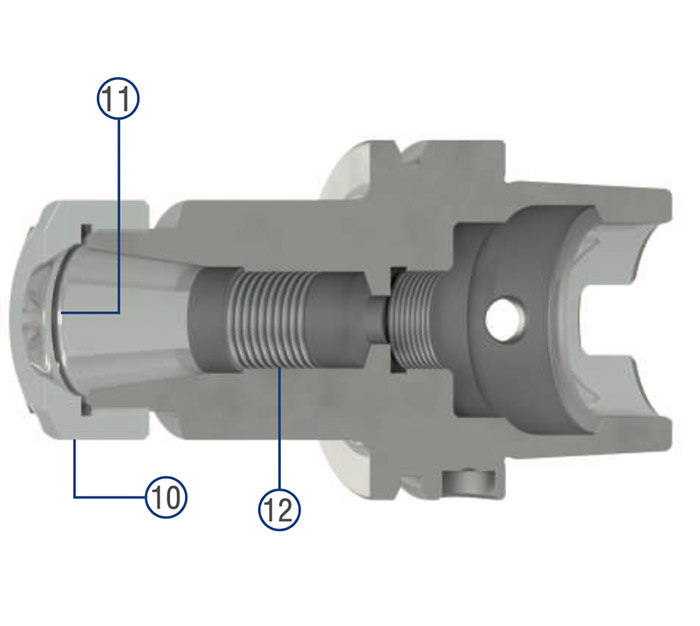

“Hawk Eye” ® Precision-ER-Collet Chuck

End Mill Holder Weldon

End Mill Holder Weldon “Cool Tool”

End Mill Holder Weldon “4 x Cool Tool”

End Mill Holder Whistle-Notch

Shrink Fit Chuck 4,5°

Shrink Fit Chuck 4,5° “Cool Tool”

Shrink Fit Chuck 4,5° “4 x Cool Tool”

Shrink Fit Chuck 4,5° “Titanium”

Shell Mill Holder

Shell Mill Holder “Cool Tool”

Combi Shell Mill Holder

Morse taper adapter with thread

Morse taper adapter with tang

Short Drill Chuck

Tool holder SK

SK 40 DIN 69871

SK 50 DIN 69871

ER-Collet Chuck

ER-Collet Chuck “Mini”

“Hawk Eye” ® Precision-ER-Collet Chuck

End Mill Holder Weldon

End Mill Holder Weldon “Cool Tool”

Shrink Fit Chuck 4,5°

Shrink Fit Chuck 4,5° “Cool Tool”

Shrink Fit Chuck 4,5° “4 x Cool Tool”

Shrink Fit Chuck 4,5° “Titanium”

Shell Mill Holder “Cool Tool”

Combi Shell Mill Holder

Short Drill Chuck

Tool holder BT

BT 30

BT 40

BT 50

Tool holder BTD

BTD 30

BTD 40

Tool holder with polygonal shank

CORUM C4

CORUM C5

CORUM C6

CORUM C8

Accessories for consistently high precision

ZUBEHÖR

Do you want to simulate your machining process or take over CAD data from our tool holders? No problem. Download all available CAD drawings in DXF format

here for free.

Karl Schüssler GmbH & Co. KG

Bahnhofstraße 108

D-72411 Bodelshausen

Phone +49 (0)7471 9590-0