The tool shrinking technology has proven itself for years in high-precision machining. SCHÜSSLER offers you a complete solution for all types of shrink fit chucks. The heart of the inductive shrink fit technology is the induction coil. The patented induction coil of the tool-manic is equipped with two separate windings, this allows them to be controlled independently of each other, resulting in an optimized heating temperature and heat distribution at the clamping area of the chuck. Therefore, shorter cycle times and a longer tool life of your chucks can be achieved. Since SCHÜSSLER offers everything from a single source, all components such as the shrink fit machine, base holder and the shrink fit chucks are perfectly complemented to each other. As a result, they obtain process reliability and consistent high quality in the shrinking processes. This guarantees highest runout and repetition accuracy for maximum tool life and protection of the machine spindle.

The different versions of the tool-manic series offer the optimal solution for any application. Also due to the help of a modular system, the shrink fit devices can be extended four your specific needs. For example, the tool-manic S20 can be extended with a cooling unit or the tool-manic S30 can be extended with the base cabinet.

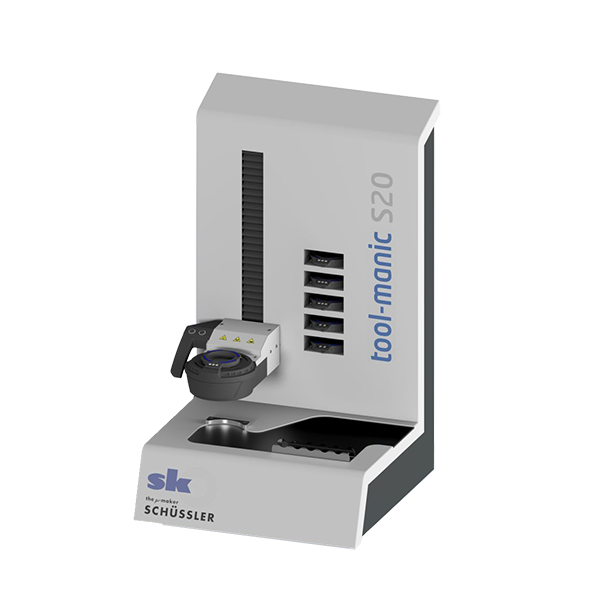

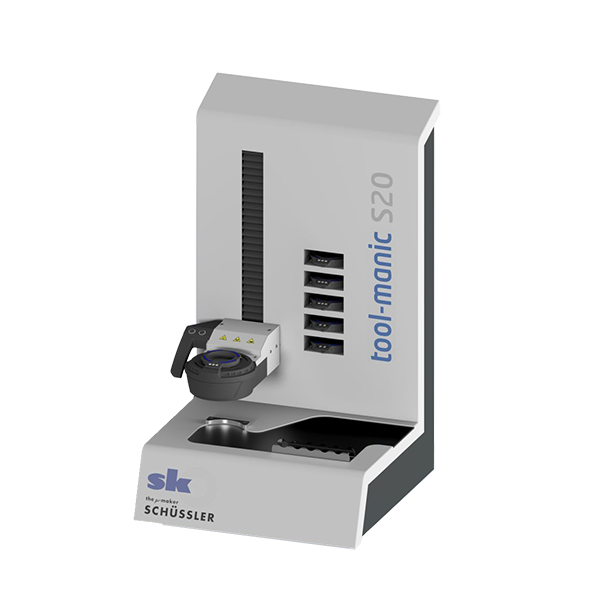

The SCHÜSSLER S20 is the perfect inexpensive entry point for your production into the inductive shrinking technology. The basic version features only the shrink fit device without a cooling unit. That is shrinking technology reduced to pure functionality. The tool-manic S20 can shrink tools up to a length of 420 mm and diameters from 3 to 32mm. Optional expansion with a cooling unit with three contact cooling adapters.

![]()

![]()

![]()

![]()

70 kg

400 V / 16 A / 11 kw

594 x 590 x 950 mm

SG-S20-01

The cooling unit offers cooling space for up to 3 shrink fit chucks with different diameters at the same time. The tool holders are cooled with a contact cooling technology, which is gentle on tools and without direct contact to water. This results in no deformation of the chuck and the runout accuracy is preserved. The cooling adapters are kept cool with a continuous flow of water. Due to the modular system the cooling unit can easily be adapted to the tool-manic S20. Because of the identical constructional components, a ground-level connection is guaranteed.

![]()

![]()

55 kg

230 V / 4,2 A / 0,58 kw

570 x 590 x 950 mm

SG-C20-01

The SCHÜSSLER S20C is the perfect mid-range shrink fit unit for your production. Due to the combination of the induction coil and integrated cooling adapters simultaneous shrinking and cooling is possible. The tool-manic S20C can shrink tools up to a length of 420 mm and with diameters from 3 to 32 mm. Cooling is done using contact cooling technology which is gentle on the tools and guarantees high runout accuracy.

![]()

![]()

![]()

![]()

![]()

125 kg

400 V / 16 A / 11 kw + Cooling 230 V / 4,2 A / 0,58 kw

1164 x 590 x 950 mm

SG-S20C-01

The SCHÜSSLER S30 is the premium product of the tool-manic series. Here, the induction coil can optionally be exchanged for an iris coil. With one turn you can set the coil to your desirable size of the shrink fit chuck. The result is the coil fits perfectly to the chuck and only the intended area is heated. In the base cabinet the water cycle cooler and accessories can be stored. It is possible to shrink tools up to a length of 560 mm and with diameters from 3 to 32 mm. Shrink parameters can be set and monitored via a 12,5” workshop-compatible touchscreen, to shrink as efficiently as possible. The tool-manic S30 is also available as a table-top unit without the base cabinet.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

280 kg

400 V / 16 A / 11 kw

1194 x 590 x 1974 mm

SG-S30-1000-01 Base Cabinet: SG-S30T-01

The SCHÜSSLER S20 is the perfect inexpensive entry point for your production into the inductive shrinking technology. The basic version features only the shrink fit device without a cooling unit. That is shrinking technology reduced to pure functionality. The tool-manic S20 can shrink tools up to a length of 420 mm and diameters from 3 to 32mm. Optional expansion with a cooling unit with three contact cooling adapters.

![]()

![]()

![]()

![]()

70 kg

400 V / 16 A / 11 kw

594 x 590 x 950

mm

SG-S20-01

The cooling unit offers cooling space for up to 3 shrink fit chucks with different diameters at the same time. The tool holders are cooled with a contact cooling technology, which is gentle on tools and without direct contact to water. This results in no deformation of the chuck and the runout accuracy is preserved. The cooling adapters are kept cool with a continuous flow of water. Due to the modular system the cooling unit can easily be adapted to the tool-manic S20. Because of the identical constructional components, a ground-level connection is guaranteed.

![]()

![]()

55 kg

230 V / 4,2 A / 0,58 kw

570 x 590 x 950

mm

SG-C20-01

The SCHÜSSLER S20C is the perfect mid-range shrink fit unit for your production. Due to the combination of the induction coil and integrated cooling adapters simultaneous shrinking and cooling is possible. The tool-manic S20C can shrink tools up to a length of 420 mm and with diameters from 3 to 32 mm. Cooling is done using contact cooling technology which is gentle on the tools and guarantees high runout accuracy.

![]()

![]()

![]()

![]()

![]()

125 kg

400 V / 16 A / 11 kw + Cooling 230 V / 4,2 A / 0,58 kw

1164 x 590 x 950

mm

SG-S20C-01

The SCHÜSSLER S30 is the premium product of the tool-manic series. Here, the induction coil can optionally be exchanged for an iris coil. With one turn you can set the coil to your desirable size of the shrink fit chuck. The result is the coil fits perfectly to the chuck and only the intended area is heated. In the base cabinet the water cycle cooler and accessories can be stored. It is possible to shrink tools up to a length of 560 mm and with diameters from 3 to 32 mm. Shrink parameters can be set and monitored via a 12,5” workshop-compatible touchscreen, to shrink as efficiently as possible. The tool-manic S30 is also available as a table-top unit without the base cabinet.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

280 kg

400 V / 16 A / 11 kw

1194 x 590 x 1974

mm

Order No.

SG-S30-1000-01

Base Cabinet: SG-S30T-01

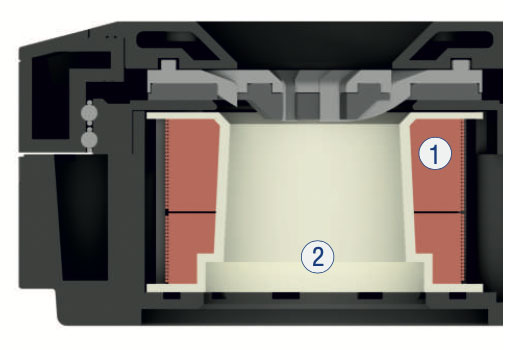

The coil technology is the heart of the tool-manic. With a new generation of coil technology, SCHÜSSLER offers an efficient, environmentally friendly, and tool-friendly shrinking process. Optimized heating parameters and shorter heating times guarantee optimal runout accuracy and a longer tool-life of the shrink fit chuck. Due to 25-30 % reduced energy consumption compared to other models the shrinking process is also significantly more environmentally friendly and energy efficient.

1. Induction coil with two separate windings. The windings are built separately and can therefore be also controlled separately. Thus, the shrinking process can be done by either the upper or the lower or with both windings together. That leads to optimized heating parameters for each shrink fit chuck, shorter heating periods and lower chuck temperatures. Due to that, shorter cycle times, short cooling times and a longer tool life can be achieved.

2. Optimized energy input into the shrink fit chuck, as only the relevant clamping area is heated. Less heat radiation downwards.*

* Only applicable when using the shrinking parameters of the S30.

3. Stop discs are encased in plastic and shock-proof.

4. Standard coils with interchangeable stop discs. Just five stop discs are enough to adapt the coil to each chuck from 3 to 32 mm of diameter.

5. Adjustable coil with monitoring of the coil position per diameter of the chuck.

6. With the help of the iris coil, the stop discs are redundant. With one turn the adjustable coil can bet set to the size of the shrink fit chuck. This results in a precise heating of only the intended area of the chuck. The result is a perfect shrinking process for the longest tool life.

SCHÜSSLER original accessories expand the application area of the tool-manic. The result is increased process reliability and overall better work processes for optimal shrinking results. Click on the info points to gain more insights into the advantages of the

tool-manic

High work ergonomics

Efficient and easy operation of the smooth-running vertical guide of the coil holder. With only one hand, the coil can be moved, and the shrinking process can be started. The clamping is done electrically and no compressed air is required.

12,5" Touchscreen

Workshop-compatible touch display for precise adjustment of shrinking parameters for optimal shrink results. Operable with gloves.

Cooling Adapters

Our cooling adapters with reducing sleeves are suitable for every type of shrink fit chuck. The heat is evenly and gentle withdrawn from the tool holder. Without direct contact to water the tool holder stays dry and stainless. There is no deformation of the shrink fit chuck and the runout accuracy is preserved.

Reducing Sleeeves

for the cooling adapters guarantee energy-efficient cooling for all diameters.

Length pre-setting

Adapter for quick and simple presetting of the protruding length of the tool up to a length of 150 mm.

Base cabinet

Storage area for accessories and the water cycle cooler. Space-saving and everything in one place.

Safety

Large storage areas, covering of hot surfaces and easy operation of the induction coil or cooling adapters guarantee ergonomic and process-safe working without the possibility of injury.

Cost-effectiveness

Since SCHÜSSLER offers everything from a single source, all shrink fit devices, base holders, and shrink fit chucks are perfectly complemented to each other. This results in high process reliability and consistent high quality in the shrinking process.

Contact cooling technology

Cooling adapters for each size of chuck, which evenly and gentle remove the heat from the tool holder. The shrink fit chuck remains dry and rust-free.

Great variety of applications

Shrinking of tools with a taper size up to max. SK 50 / HSK 100/ C8 and a tool length up to max. 560 mm.

Patented coil technology

A patented induction coil technology guarantees optimized heating parameters for each size of shrink fit chuck which leads to shorter heating times and lower tool holder temperatures therefore shorter cycle times and a longer tool life can be achieved.

Modular system

Due to the modular system the tool-manic shrink units can be expanded and adjusted to your application.

Availability

Each of the standard shrink fit units are available at a short notice. All our standard shrink fit chucks are directly available.

Environmentally friendly

Due to the 25-30 % reduced energy consumption in the shrinking process, shrinking with the tool-manic is much more environmentally friendly compared to other manufactures.

Balance Accuracy

All SCHÜSSLER tool holders are fine balanced to G2,5 at 25.000 min-1 or max. residual imbalance <= 1 gmm.

Runout tolerances

We guarantee runout tolerances < 3 µ for each of our shrink fit chucks.

Made in Germany

SCHÜSSLER has been manufacturing in Bodelshausen Germany for almost five decades. As a traditional, owner-managed family business, SCHÜSSLER stands for reliability, German thoroughness, and solution competence as well as fast reaction capability.

Karl Schüssler GmbH & Co. KG

Bahnhofstraße 108

D-72411 Bodelshausen

Phone +49 (0)7471 9590-0